Sign up for email newsletters

Sign up for email newsletters Drinks Bottling

On Jan. 24, a quiet celebration bubbled on craft brewery loading docks and dangling ski chair lifts: Beer Can Appreciation Day — a tribute to the multifaceted beer can, its historic genesis, the science behind its components and utilitarian design, and its embrace by craft beer as an artistic platform.

The evolutionary road for today’s seemingly ubiquitous vessel for Colorado craft beer has been an adventure, though.

The aluminum beer can is revered by today’s active craft beer demographic as an easy-to-pack refreshment fitting neatly in a box, cooler or backpack, and often a platform for fanciful, collectable art.

Technologically, the can may also be more highly engineered than its contents. Advanced thermodynamics and physics reveal today’s beer cans are more efficient to fill, pick up and cool than glass. Their internal surfaces also bear advanced flavor-protecting coatings, and most have been recycled at least seven times before they end up in your frig.

The quantity of usable space for labeling, as well as the overall shape and contours, has been carefully refined over a century.

From the automated assembly of its parts to the current mouth opening shape that allows beer to breathe while one drinks, the nonlittering opener lever, and the advanced fill and carbonation sensors of modern canning lines, today’s beer can sits at the confluence of social and technological crossroads.

Ironically, craft beer was late to adopt the can, despite the industry’s embrace of it today. The first canned beers were experimental flat-top steel and tin containers introduced by Pabst and Anheuser-Busch just in time for Prohibition. As temperance eased, the Gottfried Krueger Brewing Company of Newark, New Jersey, conducted the first serious commercial can run in 1935, using a can design that opened with a piercing tool.

Later that year, Schlitz introduced a can sealed with a crimped crown cap like a beer bottle: the “cone top.” The next year, Pabst introduced the tinplate prototype of today’s beer can. It featured a lightweight top plating and sealing design that became scarce as World War II heated up and common metals were diverted to war efforts. Innovation looked to other lightweight metals though, and the hallmark for today’s tin-free beer can emerged as the war ended, offering a sustained freshness achieved with resin coatings and linings that bottled beer could not match.

In 1959, Coors is credited with perfecting the aluminum beverage can for regional brewers, breaching into a space nationally distributed brewers usurped after the war to beat smaller brewers to market. The price of aluminum lowered entry costs, yet few regional breweries chose to retrofit their bottling lines for canning due to the perception that fine beverages came in bottles.

As craft beer emerged in the 1980s, its brewers mainly packaged in bottles too, apart from a few runs of Pete’s Wicked Ale in the mid-1990s. One reason being that craft brewers rarely had systems large enough to meet the volumes needed to fill a typical run on canning lines available at the time.

When Oskar Blues went all-in on cans in 2002 though, the conversation forever changed. And three years later, when The New York Times anointed Dale’s Pale Ale with greatness, suggesting the can might be the secret factor to protecting the beer’s flavor, mobile canning lines and local businesses catering to craft beer canning proliferated. A new paradigm then dawned as Colorado consumers discovered that canned craft beer paired with outdoor recreation and fit an environmentally conscious niche.

Today, Boulder County’s best beers are found almost exclusively in cans.

While the beer can and its golden contents are works of art, can labels too have taken on identities of their own. From cans directly printed with psychedelic brand images at Ball Corp., Crown Holdings or other manufacturers, to ornate heat-shrink label sleeves (e.g., Liquid Mechanics) and vinyl printed sticker labels (e.g., Wibby and Crystal Springs), getting a brewery’s brand noticed takes many forms.

A quick survey of local brands reveals not only these labeling techniques, but sometimes two at a time, as breweries like Avery cleverly repurpose direct-printed cans with sleeves or full edge labels.

The catalyst for successfully canning beer at scale was once tied to an effort to ship millions of beers to soldiers overseas in World War II. Canning beer has evolved since then to become a fixture of craft beer — a refreshing companion while plunging a river, summiting a 14er, or rolling a gravel track — always perfectly pressurized, delicious and ready for you to say “ah.”

Cyril Vidergar can be reached with ideas and comments at beerscoop@gmail.com.

Sign up for email newsletters

If you’re in the market for a new home in Longmont, Colorado, securing a home loan may seem like a...

Since the 1930s, the Longmont Chorale has presented concerts that thrill and delight. Members span all musical skill and experience...

Are you going on vacation, and need a trusted kennel for your dog? Happy Hounds provides exceptional dog boarding in...

Jones Excavating and Plumbing has provided complete excavation services to Colorado homeowners and contractors. They are the experts to call...

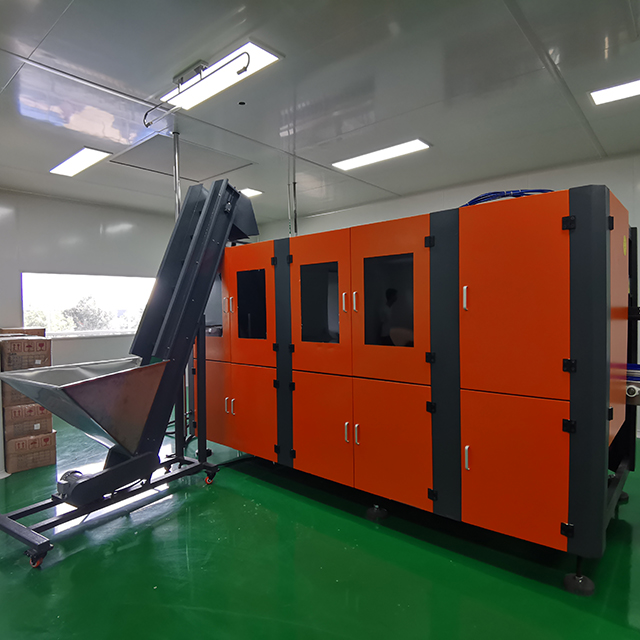

Carbonated Drink Filling Line Looking for an apartment in desirable south Boulder? Take a look at Flatiron View one and two bedroom apartments. These...